.png)

V Belt Dimensions(inch)

V Belt Transmission Design

V-belts are quite common within the industry and in various items of machinery and are quite adaptable to many applications. Typically, V-belt drives operate best at speeds between 8 and 30 m/s (1,500~6,000 ft/min). V-belt drives permit large speed ratios, are easily installed and removed, quiet, and low maintenance.

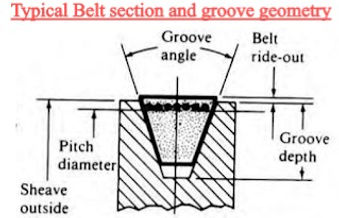

Pulleys and belts have two uses: to transfer power from one shaft to another and to increase or reduce speed or torque. This is done by using pulleys of different pitch diameters. The pitch diameter of a pulley is not the outside diameter, nor is it the inside diameter. In fact, the pitch diameter is very difficult to measure directly. If you cut a belt and look at the end, you'll see a row of fibers or cords near the outside surface. This is the tension carrying part of the belt - the rest of the belt exists only to transfer the forces from the pulley to and from these cords. The pitch diameter of any pulley is measured at these cords. Note that the pitch diameter of a pulley depends not just on the pulley itself, but also on the width of the belt. e.g. A wider belt on a narrower pulley will ride higher than usual in the groove increasing the effective pitch diameter.

While they transfer torque effectively, they lose a bit of speed as the belt stretches under load. Sometimes there is a slip of the belt on the pulleys, but in a properly set up transmission, there should be no slip. The tension of the belt should be sufficient to prevent slip. There is a creep, however, but creep, not to be confused with slip, is due to belt elements changing length as they travel around the pulleys, and since the pulley is rigid then there must be relative motion between belt element and pulley. This is normal operation and expected.

In most applications, the pulleys are different effective diameters and the driving speed is different from the output speed. It is the pitch diameter of each of the pulleys which determine the drive ratio. Note that pulleys no not affect power, when they increase torque, speed reduces, and vice versa.

The general geometry of a V-belt drive and the typical cross-section of belt and pulley are shown below:-

The driving side pulley (connected to the power source) and pitch diameter D1 is at the left and rotates counter-clockwise at speed n1. The driven pulley has a pitch diameter of D2 and rotates at speed n2. The wrap angle of the belt on the pulleys is θ1 and θ2. Note that there is a 'tight' side and a 'slack' side to the belt when it is transmitting power, and the difference in the tension between these 2 sides is proportional to the amount of power transferred. Power is typically transferred with the tight side at the bottom. Note however that there must be a static tension in the belt, even when stationary, to provide sufficient friction for the pulley to drive the belt and not slip, and this tension is the same value top and bottom at rest.

The size of a pulley is indicated by its pitch diameter (D), which slightly smaller than the outside measured diameter. The center distance between the shafts is indicated as C in the diagram.